- Phone:+86 15218629499

- Phone: +86 15766990063

- E-mail: Yzprinting01@163.com

In the fast-evolving world of retail, plastic bag printing plays a critical role. As businesses seek innovative packaging solutions, understanding the best printing techniques becomes essential. According to industry expert Sarah Wilson, “Effective plastic bag printing can elevate a brand's visibility and engage customers.” Companies must navigate numerous methods to find what fits their needs.

Plastic bag printing options include flexography, gravure, and digital printing. Each technique offers unique advantages and challenges. For example, flexography is cost-effective for large runs, while digital printing allows for customization. Small businesses may struggle to decide the best fit for their product lines.

Choosing the right method isn’t always straightforward. Every printing technique has limitations and considerations, such as setup time or color precision. Reflection on these factors can lead to better choices. A well-chosen plastic bag printing approach can lead to increased brand recognition and customer loyalty.

When considering plastic bag printing techniques, several options stand out.

Flexographic printing is widely used for its speed and versatility. It allows for high-volume production while maintaining quality. This method works well for vibrant colors and intricate designs, making it popular among businesses seeking to make a statement.

Another technique is gravure printing. This process excels in creating detailed imagery and gradients. However, it comes with a higher initial cost and longer setup times. Businesses need to weigh these factors against their budget and time constraints. Eco-solvent printing offers a more environmentally friendly alternative. While it may not achieve the same color vibrancy, it appeals to environmentally conscious brands.

Exploring digital printing provides flexibility for smaller orders. However, the cost per unit can be higher compared to traditional methods. Many companies find themselves questioning which method best fits their needs. It's essential to consider design complexity, order volume, and desired impact. Balancing these elements can lead to better decision-making in plastic bag printing.

Choosing the right printing method for plastic bags is crucial. The printing technique affects the bag’s durability and visual appeal. Research shows that 55% of consumers notice packaging design first. This highlights the importance of high-quality printing methods.

Flexographic and digital printing are popular options. Flexographic printing allows for high-speed production. It is ideal for large runs and offers vibrant colors. However, setup costs can be high. Digital printing has a lower setup cost and works well for smaller batches. It provides excellent detail but may not be as cost-effective for larger orders.

Consider the materials used in your bags. Different printing methods work better with specific materials. For example, some inks may not adhere well to certain plastics. Additionally, environmental factors matter. In a recent survey, 72% of companies indicated that sustainability is a priority. Selecting eco-friendly inks and processes can enhance your brand image. There are pros and cons to each method, so reflect carefully on your business needs.

When it comes to printing on plastic bags, businesses have various techniques to choose from. Flexographic printing is the most popular method. It allows vibrant colors and quick production. According to recent industry studies, 75% of companies prefer flexographic printing for its efficiency and cost-effectiveness. This technique works well for large batches, making it ideal for mass production.

Another technique worth considering is digital printing. This method is gaining traction because of its flexibility. It requires less setup time and is perfect for smaller orders. A report from a leading printing association states that digital printing has grown by 25% in the past year. Brands that need customization often leverage this method to create unique designs without heavy upfront costs.

**Tips:** Always consider your target market when choosing a printing method. Reflect on what aligns best with your branding and budget. Quality should not be sacrificed for speed. Look into options that allow for eco-friendly inks and materials. Evaluating these can lead to better decisions for long-term success.

| Printing Technique | Description | Best For | Pros | Cons |

|---|---|---|---|---|

| Flexographic Printing | A high-speed printing process using flexible relief plates. | High-volume orders | Cost-effective for large runs, vibrant colors. | Initial setup cost, limited to simpler designs. |

| Digital Printing | Direct printing from digital files without printing plates. | Small orders and custom designs | Quick turnaround, full color printing. | Higher cost per unit for large quantities. |

| Screen Printing | Involves pushing ink through a mesh screen to create a design. | Colorful, high-quality images | Durable prints, vibrant colors. | Not ideal for complex images, slower process. |

| Gravure Printing | Uses engraved cylinders to transfer ink to the substrate. | Large scale production | High quality, detailed images. | High initial costs and setup time. |

| Offset Printing | Transfers ink from a plate to a rubber blanket and then to the bag. | Medium to high-volume orders | Excellent quality and color consistency. | Not cost-effective for small runs. |

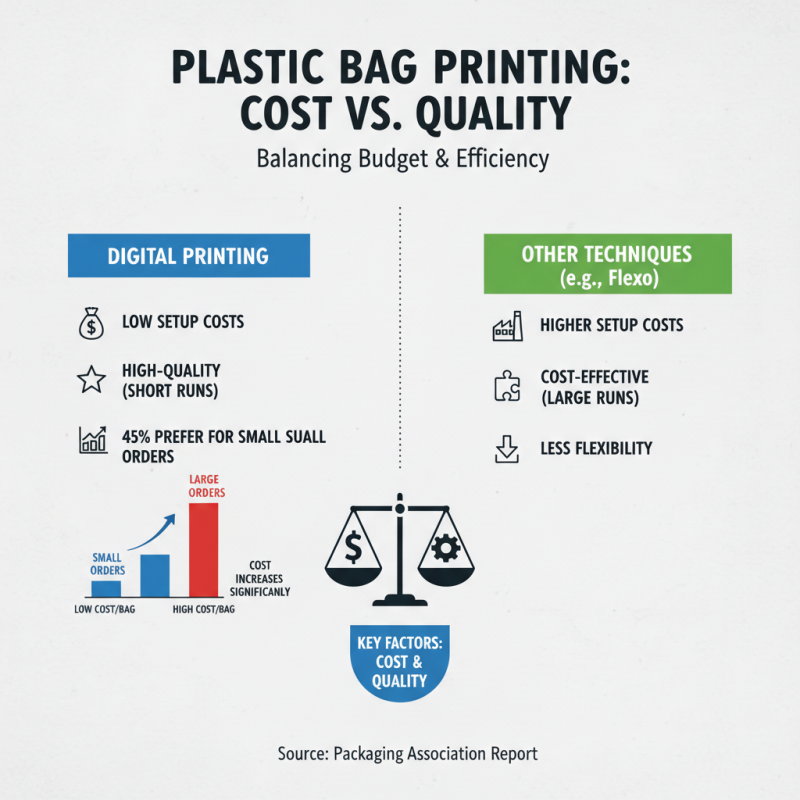

When evaluating plastic bag printing techniques, cost and quality are critical factors. Recent industry reports indicate that digital printing has gained popularity due to its low setup costs. This method provides high-quality results, especially for short runs. A survey from the Packaging Association found that 45% of businesses prefer digital printing for small orders. Yet, the cost per bag increases significantly with larger orders. Companies must balance their budget against production efficiency.

Another technique, flexographic printing, offers better pricing on bulk orders. This method uses faster production speeds, driving down costs. According to a 2022 market study, businesses that use flexographic printing see a 30% reduction in costs for bulk runs. However, the quality may not meet high standards for intricate designs. Some companies report issues with color consistency.

Evaluating these methods reveals a trade-off between cost efficiency and quality. A business needs to understand its target market's demands. Focusing solely on lower costs might compromise the visual appeal of the product. Ultimately, businesses should consider both factors carefully to enhance their brand image.

As businesses seek sustainable solutions, plastic bag printing technology is evolving. The industry is moving towards eco-friendly materials. Biodegradable options are gaining traction. These bags reduce environmental impact while maintaining functionality. Brands are now focusing on recycled plastics for their bags. This shift can resonate with eco-conscious consumers.

Digital printing is revolutionizing the way designs are created. High-resolution images and vibrant colors are now possible. This method reduces waste and allows for customization. Smaller runs of bags can be printed with ease. It gives businesses more flexibility. However, not all businesses may have access to this technology yet.

Another trend to watch is automation in printing processes. It enhances efficiency and speed. Yet, the initial investment can be daunting for smaller companies. The quality varies across different technologies. Companies must consider whether automation truly meets their needs. Experimentation with these trends is necessary for growth.