- Phone:+86 15218629499

- Phone: +86 15766990063

- E-mail: Yzprinting01@163.com

The plastic wrapper industry is undergoing significant transformations as we approach 2026. According to a recent report by the Plastics Industry Association, the global plastic packaging market is projected to reach $1 trillion by 2026. This surge is driven by consumer demand for convenience and sustainability. Industry expert Dr. Emily Carter stated, "Innovations in plastic wrapper technology can redefine packaging solutions while addressing environmental concerns."

Eco-friendly materials are gaining traction. Many brands are exploring biodegradable and compostable wrappers. This shift comes as consumers are more mindful of their environmental impact. The challenge remains to balance sustainability with product protection. Experts emphasize that not all biodegradable wrappers perform well under real-world conditions. It’s a critical area that demands further research and development.

As we look ahead, advancements such as smart coatings and recyclability improvements are on the horizon. However, the journey is not without hurdles. The industry must confront issues like waste management and consumer education. The future of plastic wrappers hinges on collaboration across the supply chain. Engaging consumers in this dialogue is vital for driving meaningful change.

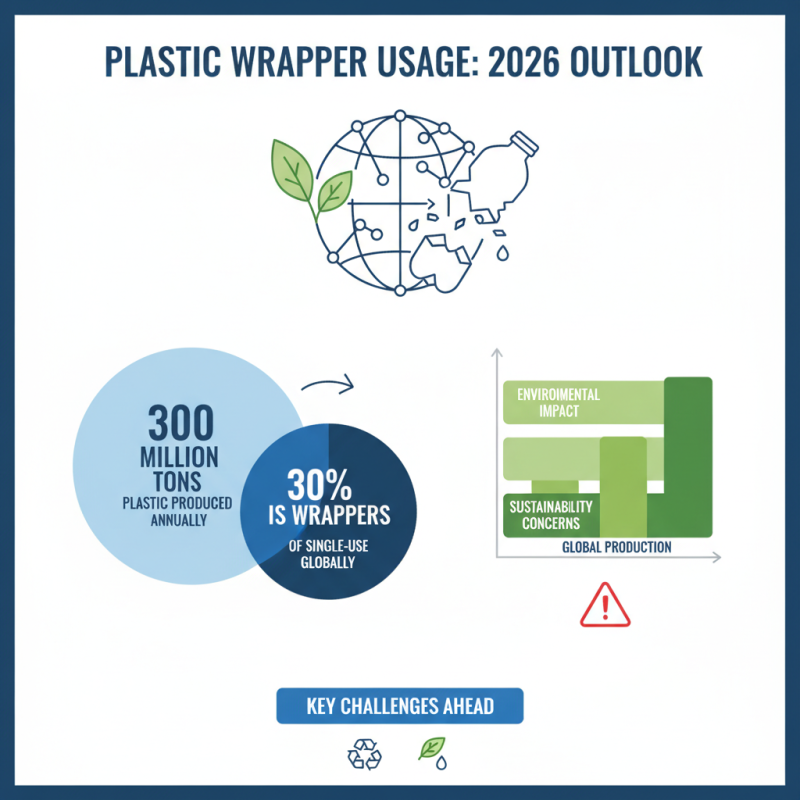

As we look into 2026, the state of plastic wrapper usage displays a complex landscape. Recent reports indicate that about 300 million tons of plastic are produced annually, with wrappers making up a significant percentage. That's roughly 30% of single-use plastics globally. This level of production raises pressing concerns about environmental impact and sustainability.

Innovation is critical in addressing these challenges. Some companies are exploring biodegradable alternatives. These new materials may reduce landfill contribution significantly. Yet, many current innovations still rely on traditional plastics, which complicates recycling efforts. It is estimated that only 9% of plastic waste is effectively recycled. The performance of these innovative materials often lags behind conventional options, leading to consumer hesitance.

Tips for consumers include choosing products with minimal packaging. Support brands that use sustainable materials. Small choices can lead to larger changes in the industry. Awareness is key. While exciting trends are emerging, the dependence on plastic remains concerning. More effort is needed from both consumers and producers to create a truly sustainable packaging ecosystem.

The landscape of plastic wrapper production is evolving. Emerging materials are at the forefront of this change. Biodegradable plastics are gaining traction. These materials appeal to eco-conscious consumers. They break down more easily than traditional plastics. Innovations like plant-based polymers are crucial. They offer a more sustainable alternative.

Technology is also pushing boundaries. Advanced manufacturing processes improve efficiency. 3D printing methods enable unique designs. These innovations create custom packaging solutions. However, it's not all perfect. Some biodegradable options still face durability issues. The balance between environmental impact and functionality remains a challenge.

Recycling technologies are developing rapidly. Improved sorting systems enhance plastic recovery. However, many wrappers still end up in landfills. This raises questions about true sustainability. Companies must focus on the entire lifecycle. Transparency in sourcing materials is essential. The quest for better solutions continues.

This chart showcases the projected growth of various sustainable materials and technologies in plastic wrapper production for 2026.

Sustainability is changing the plastic wrapper industry. A recent report indicates that over 60% of consumers prefer eco-friendly packaging. This demand is driving innovations in materials and processes. Biodegradable wrappers are becoming more common. They break down naturally, reducing waste in landfills.

Yet, challenges remain. The production costs for sustainable materials can be higher. Many brands are hesitant to transition fully due to financial concerns. A survey shows that 70% of companies still rely on traditional plastic. This reliance complicates efforts to reduce environmental impact. Additionally, consumer education on recycling is often lacking.

New technologies are emerging to address these issues. For instance, edible wrappers are being developed. These could replace conventional plastic, offering a dual benefit. However, scalability is a question. Can they be produced widely enough to make a difference? The path forward isn’t straightforward, but the push for sustainability is clear. The industry faces a crucial turning point.

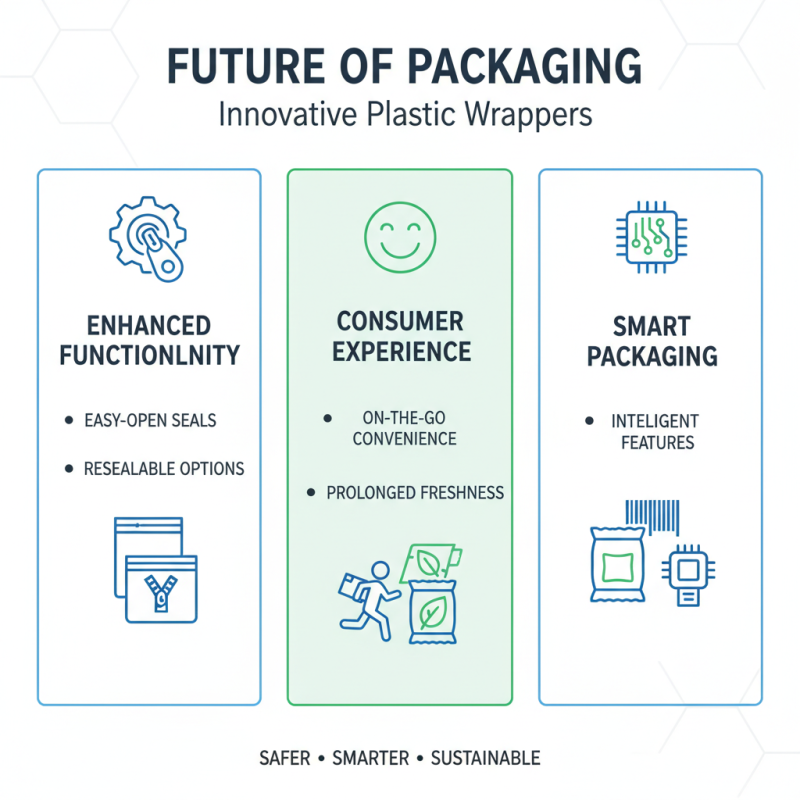

Innovative designs in plastic wrappers are transforming how products are packaged. The focus is on enhancing functionality while improving the consumer experience. Smart packaging features are emerging. These include easy-to-open seals and resealable options. Such designs aim to create convenience for consumers on the go. For those who value freshness, these innovations keep products safer for longer.

At the same time, the aesthetics of packaging matter. Eye-catching visuals attract consumer attention. Bold colors and unique shapes create a lasting impression. However, not all designs resonate. Some wrappers may look great but are difficult to handle. Functionality must balance with visual appeal. This challenge requires constant adjustment and creativity.

Sustainable materials are becoming a priority. Consumers are increasingly aware of their impact on the environment. Yet, some innovations in materials face scrutiny. Not all alternatives meet durability standards. Finding a balance between eco-friendliness and quality is crucial. The journey is ongoing. The industry must remain adaptable and open to feedback. There’s still room for improvement. Each step reflects the evolving needs of consumers.

The plastic wrapper industry is undergoing significant changes due to evolving regulations. These changes aim to reduce plastic waste, driving manufacturers to innovate. According to a recent report by Smithers Pira, the global market for sustainable packaging is expected to reach $1 trillion by 2027. This shift creates both challenges and opportunities for businesses in the sector.

Regulatory frameworks are tightening, especially in regions like Europe. The European Union has implemented the Single-Use Plastics Directive. This aims to ban specific single-use items by 2021. Compliance requires manufacturers to rethink designs and materials. Additionally, in the United States, states like California are enacting stricter recycling laws. These laws encourage recyclability and compostability in packaging. But not all companies are prepared for this transition.

Tips: Evaluate your current packaging materials. Shift towards biodegradable options when possible. Engage with stakeholders to keep abreast of changes. Industry reports suggest that companies embracing sustainable practices can see increased consumer loyalty. As regulations evolve, brands must adapt quickly. The future landscape might become challenging without proactive measures.